- 03 9359 0688

- info@alfex.com.au

- Mon - Fri: 8:30 - 17:00

- Laser Systems

- Epilog Laser Systems

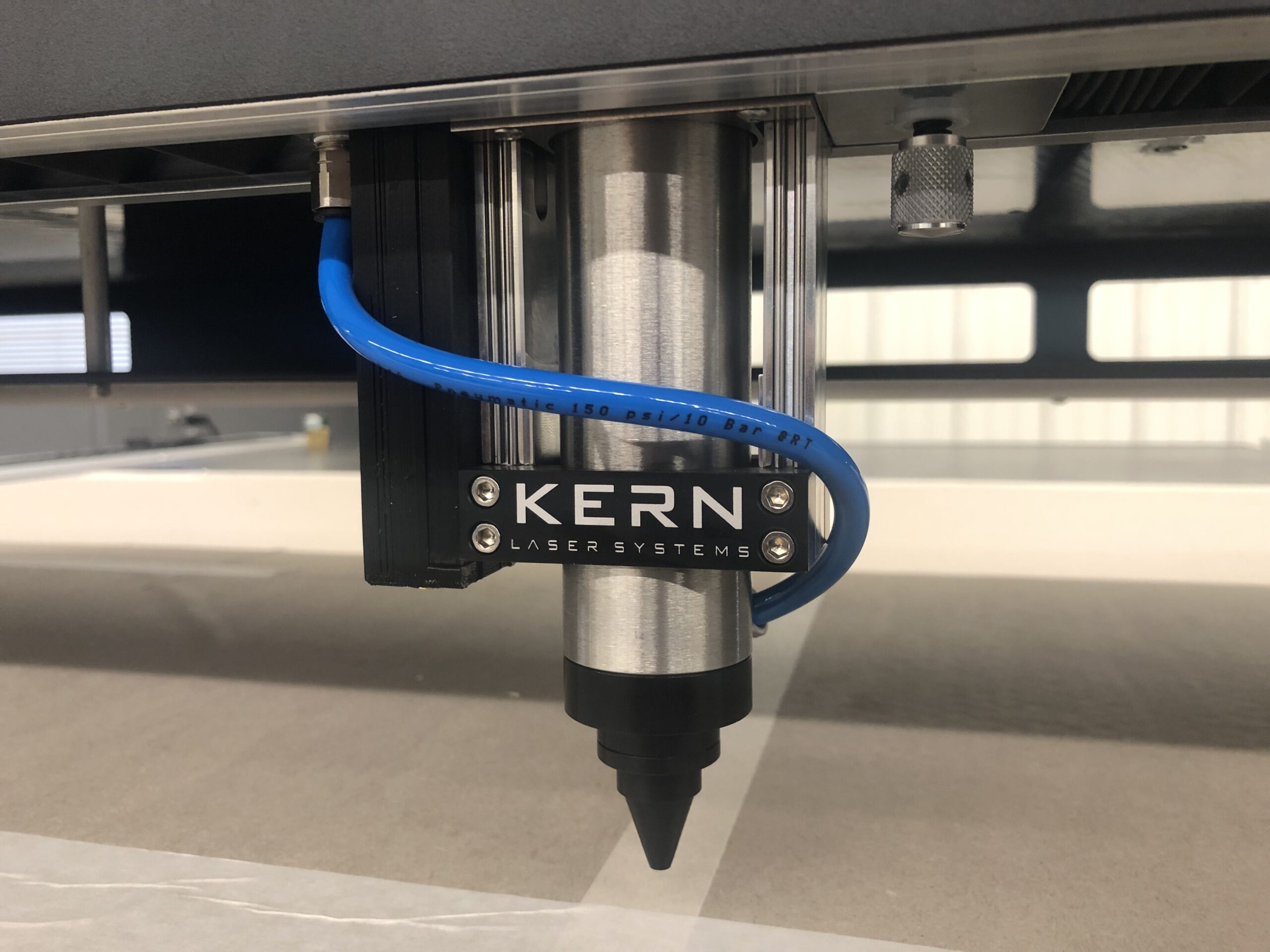

- Kern Laser Systems

- Lotus Laser Systems

- Vision Engraving Systems

- ACSYS Lasertechnik

- BOFA Fume Extraction

EpilogLaser Systems

Kern Laser Systems

Vision Engravers

- Additive 3D Printers

Desktop 3D Printers

Industrial 3D Printers

Metal 3D Printers

- CNC Machine tools

Haas Rotaries and Indexers

Haas Automation Systems

- Online Store

- Service Request

- 1300 20 15 10

VIC | NSW | QLD | SA | WA